UAF Community and Technical College expands 3-D printing lab

September 30, 2016

Karalee Watts

907-455-2833

The University of Alaska Fairbanks Community and Technical College drafting program has added 16 new 3-D printers to its downtown lab.

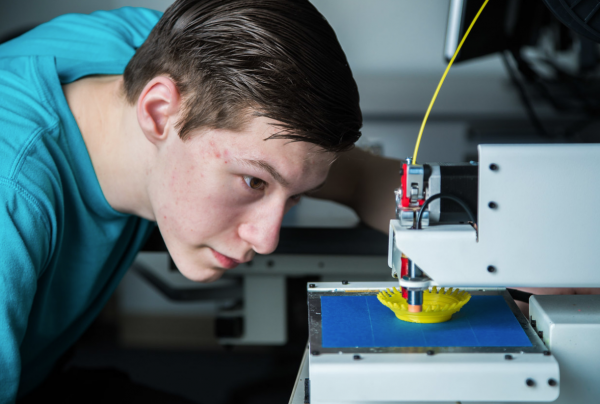

The lab seems much like a standard computer lab, but each computer has a 3-D printer. The lab now has 20 such student workstations. Larger special-purpose printers sit against a back wall.

With the ability to take a virtual design and turn it into a physical object, 3-D printers have become popular for quick fabrication of scale models or parts. Recent improvements have made the printers more accessible, but users still need to know the computer software and printing process.

CTC purchased the printers with an $11,300 grant from the Alaska Technical Vocation Education Program, part of the Alaska Department of Labor and Workforce Development.

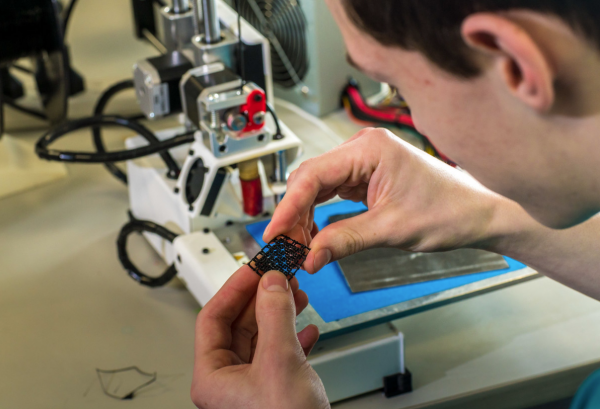

The CTC program is shifting focus from traditional drafting to a more industry-relevant combination of drafting and design technologies. The printers give students hands-on experience in those fields.

Until recently, students had just four printers to share in each class. Wait times were sometimes long. Depending on the project and desired print quality, prints can take anywhere from a few minutes to several hours to complete.

Joel Sturm, the program assistant responsible for the maintenance and operation of the 3-D printers, said the four student printers were in use nearly 100 percent of class time. Now, students are able to consistently see their designs come to life without waiting in line.

“Being able to turn a digital part into a real one can help solidify the concepts of computer-aided design,” Sturm said.

Modeling and printing instructor Adam McDermott described the new machines as fused filament fabrication printers. Much like thread in a sewing machine, spooled plastic filament feeds into the printer, which melts it and places it in precise layers.

The printers have an open design, which allows students to watch the process.

The lab also houses a printer used for projects such as topographical maps, binding together gypsum powder with the ability to color the print with ink. Students can also take on unique and quirky challenges — a few semesters ago, they designed and printed a small green latch to fix a broken paper towel dispenser in the building.

The lab also recently acquired an extruder that allows users to produce their own filament from small plastic beads or even shredded recycled plastic. “This allows us to reuse failed or unwanted prints as material to turn back into filament,” Sturm said.

CTC offers beginning, intermediate and advanced courses in computer-aided design, 3-D modeling, assembly and animation. The courses focus on the computer software used to create 3-D models and the technology and hands-on experience of printing those models.

“There are endless career opportunities available to students that can fabricate, assemble and animate models on the computer. There will always be a need for parts for machines, printers, computers, assembly lines, interiors of trucks, chainsaws, medical applications, prostheses and countless other pieces of things,” McDermott said.

In drafting, students with these skills will be well positioned for employment within local architecture and design companies.

“As more people become proficient at 3-D printing, the community will benefit,” McDermott said. “Especially since we are in Alaska and the shipping of parts from the Lower 48 takes time and money to arrive here. In our lab, a student can come in with an idea of an item, model it and print it within minutes in most cases.”

Sturm also believes this will benefit local businesses in need of rapid prototyping.

“I've worked with jewelers in Fairbanks whose jewelry starts as a 3-D model. Pretty much any business that has a shop and does custom work can benefit from 3-D printers,” he said.

CTC occasionally offers one day 3-D printing introductory workshops throughout the school year for a $40 fee. Sturm is also available to arrange visits to the lab by appointment. He can be contacted at jsturm8@alaska.edu.